Replacement Parts

TRICENTRIC® and HIGHSEAL® components are manufactured under an audited and registered quality system and are designed in a permitted engineering facility to meet OEM quality and engineering standards ensuring:

- Large stock of standard and special spare parts and cast components;

- Quick turnaround on all non-standard components; and

- Fully warranted OEM parts of uncompromising quality.

Ensuring expedited replacement parts, the SCORE VALVES family group of companies employs over 150 personnel and includes:

- Full design, fabrication, machining, welding, NDT inspection, valve modification, and pressure testing to 84” and larger and

- All parts are manufactured under an ISO 9001 quality management system.

Contact a distributor in your region or Score Valves directly for replacement parts.

Maintenance Service

Service to TRICENTRIC® and HIGHSEAL® valves can be performed at SCORE VALVES’ 30,000 sq ft facility or at the end-user site, as required. Our valve facility is Boiler Safety Association Authorized (ABSA) for the construction, repair, and alteration of Category C fittings to provide:

- Dedicated customer-focused personnel and

- OEM-authorized service crews.

Ensuring expedited service and repair work, the SCORE VALVES family group of companies employs over 150 personnel and boasts:

- Full design, fabrication, machining, welding, NDT inspection, valve modification, and pressure testing;

- Test stands and testing plates to 84” CL300 capable;

- Ambient, cryogenic, high-temperature, and emissions testing;

- Actuation, controls, and accessory mounting and testing;

- Audited quality management and facility cleaning processes by the FDA and major oil & gas, aerospace, and air separation organizations;

- Heat treatment furnaces; and

- Welding using ASME Section IX qualified weld procedures and welders, including WCB, LCB, WC6, WC9, C12, C12A, 304, 316, 321, 317, duplex, alloy 20, Monel®, Inconel®, Hastelloy®, titanium, and cobalt alloys.

Contact a distributor in your region or Score Valves directly for service inquiries.

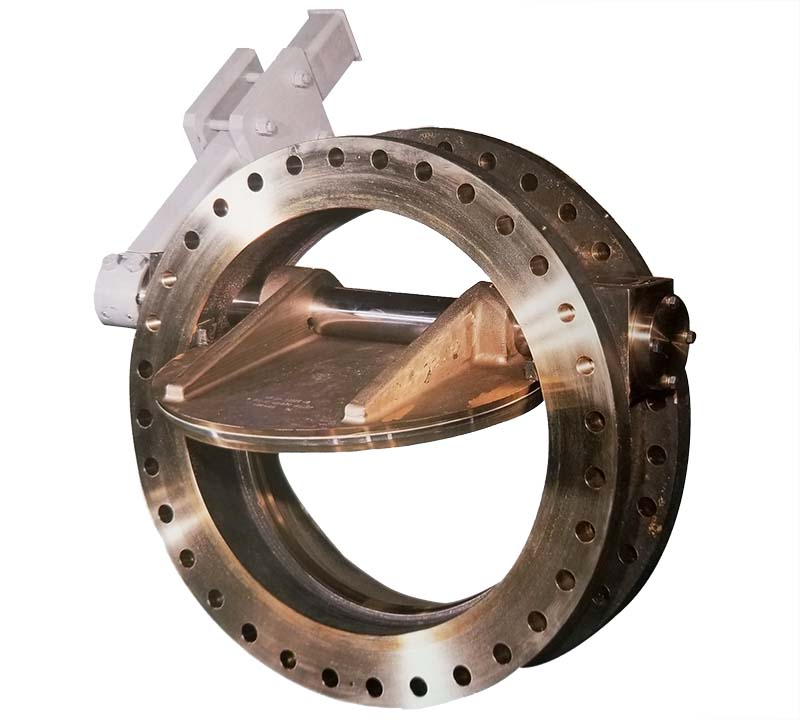

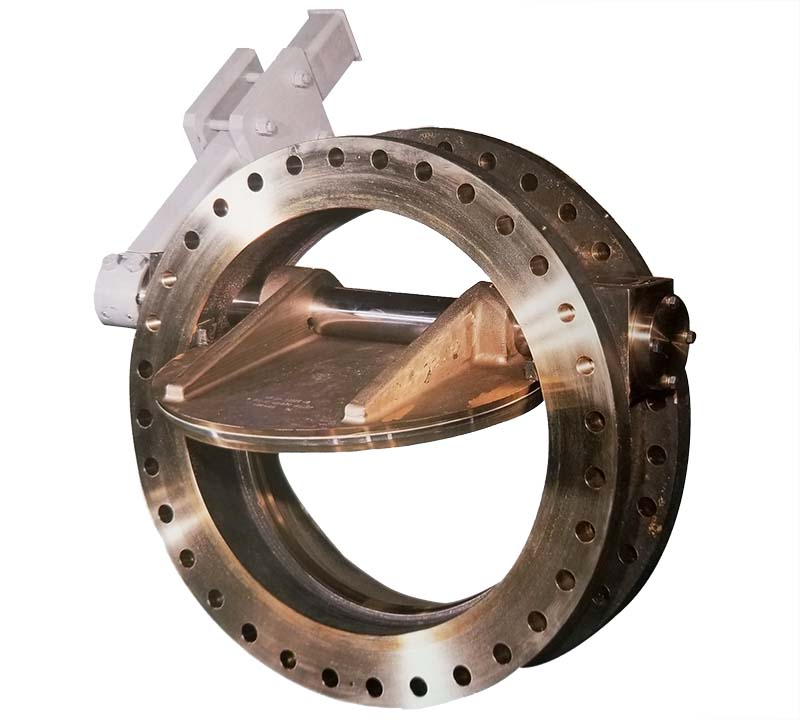

Legacy Products

SCORE VALVES provides complete end-user support for all TRICENTRIC® and HIGHSEAL® valves manufactured since the mid-1970s including complete duplicate valve replacement, replacement parts, and maintenance and repair services.

Over the last 50 years the TRICENTRIC® and HIGHSEAL® valve install base has grown to include thousands of application solutions with unique designs for valves.

Types: double and triple offset butterfly; triple offset wafer check; and damper valves.

Styles: plain wafer, lugged wafer, double flanged, welded end, clamp joint end, RTJ, tongue and groove, O-ring, flat face, ASME B16.47 Series A & B, ASME B16.1, DIN, and AWWA among others.

Sizes: full port from 3” to 84” as well as reduced port from 4″3″ to 26″24″ to highly reduced ports such as 24″8″.

Pressure classes: full rated from CL150 to CL150 and reduced rated from CL150CL75 to CL1500CL150.

Material configurations: carbon, alloy, stainless, super austenitic, and duplex steels; bronze; Monel®; Inconel®; Hastelloy®; and titanium materials with specialty surfacing including HVOF; flame spray; chrome; nickel, copper, and silver plating; ceramic, TFE, PTFE, and titanium-nitride plasma vapor deposition coatings.

Options: Steam/heat transfer liquid tracing for jacket, disc and shaft; cryogenic & high temperature extensions; LOX/LH2 polymer seat; CCW to close; block and bleed to OSHA and API; 3-way linked valves; splined high-vibration; controlled orifice disc; vacuum service; purged packing and bearings; outboard bearings; live loaded packing; orifice plates; spool pieces/ spacer plates/ tees; heat shields; gears/ actuators/ accessories; rigid and flexible extensions; process controlled NDE/ weld metallurgy/ heat treatment/ NACE MR0103 and MR0175/ NASA specs./ welding/ material origin; FDA Audited cleaning to O2, Cl2, pickled and passivated to ASTM; testing to cryogenic BS6364, MSS and NASA specs.; high temperature testing to 1400° F; and fugitive emission testing.