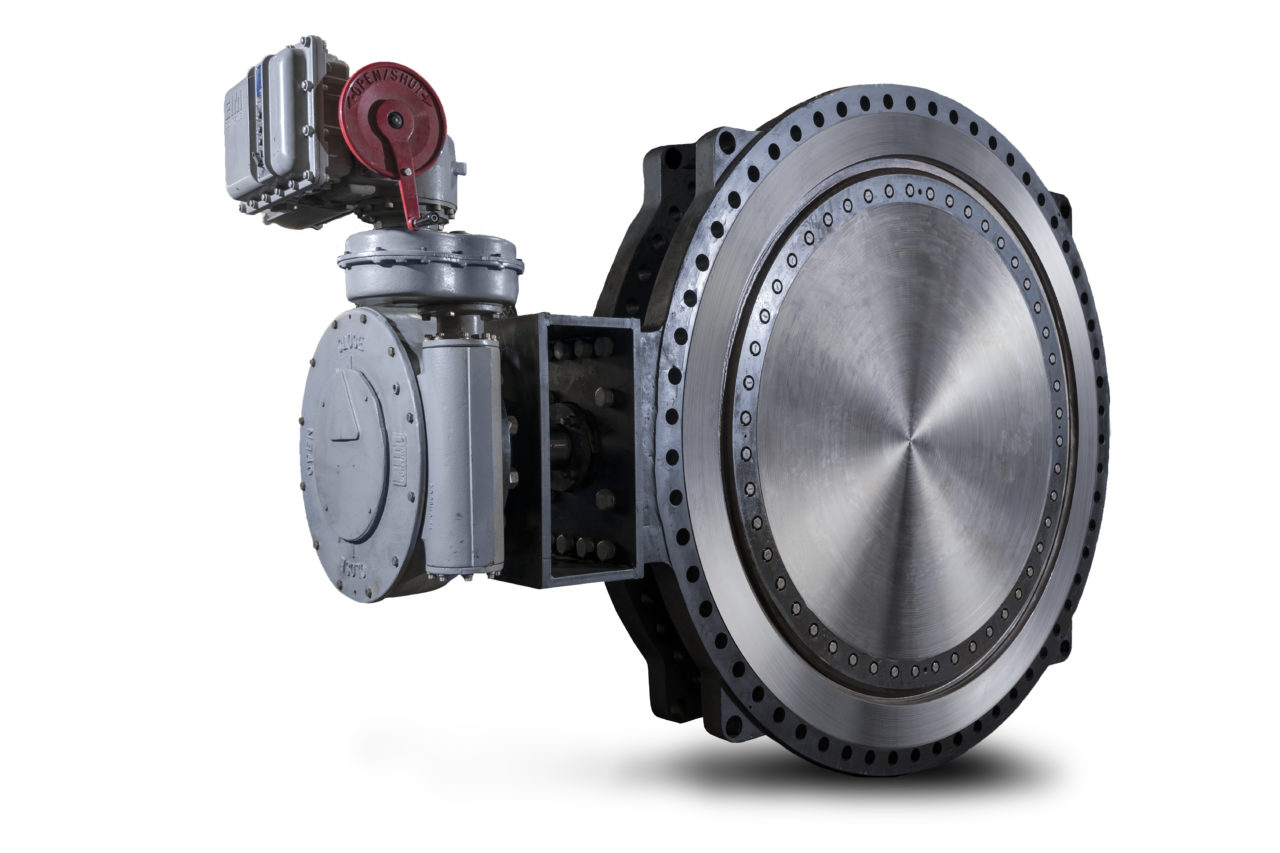

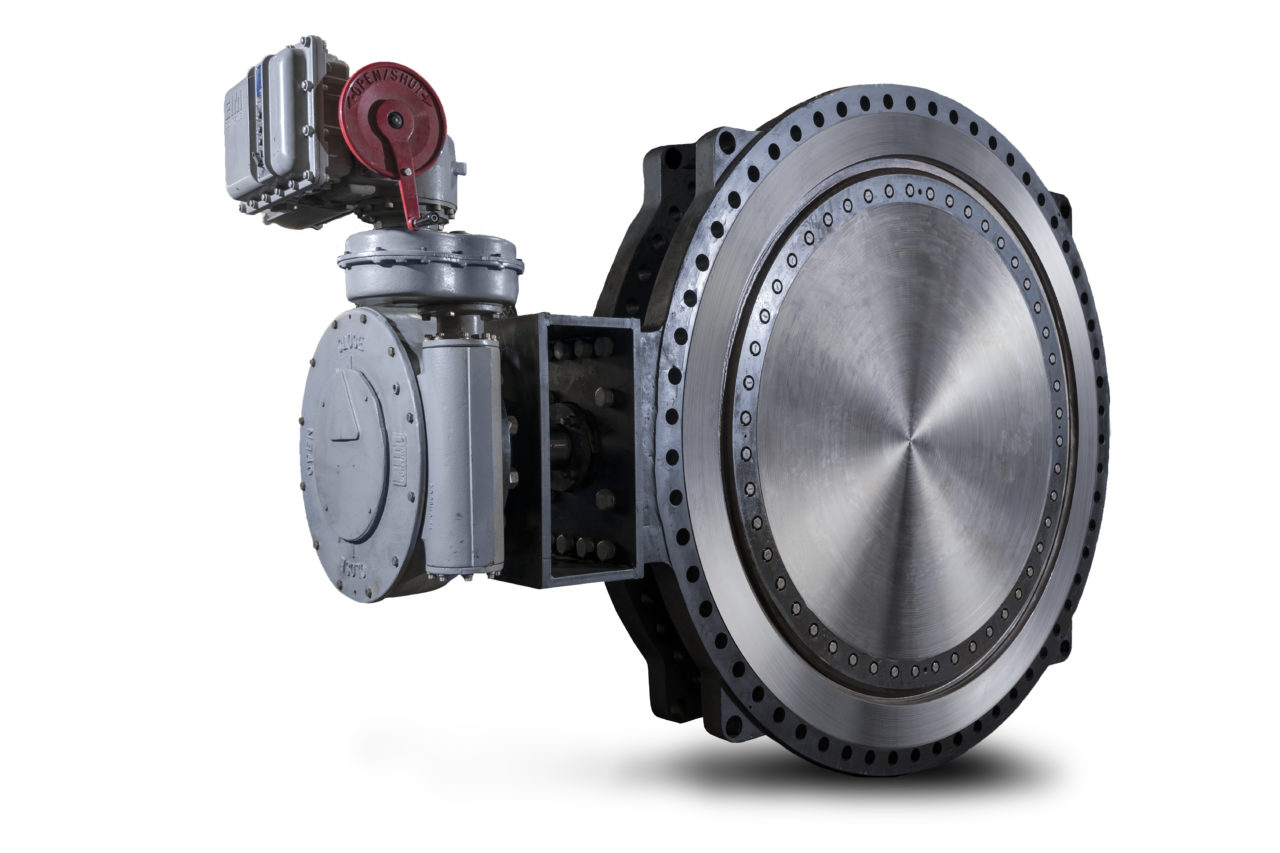

TRICENTRIC® DESIGN

The TRICENTRIC® triple offset valve is a brand leader in shutoff performance and dependability. As the first North American design, with over 50 years of global install base experience, the proven non-rubbing closure performance exceeds end-user demands across a wide range of applications.

HIGHSEAL® DESIGN

With over 40 years of global install base experience, HIGHSEAL® double offset and concentric butterfly valves provide a variety of design configurations, styles, and materials for cost-effective solutions to suit every application across today’s process industries.

COMPLIMENTARY PRODUCTS AND SERVICES

SCORE VALVES also provides gear operators; actuators with accessories; pipe spools; spacers; tees; extensions; testing for ambient, cryogenic, high temperature, and emissions; and engineering support for application design, material selection, and sizing.

Parts, Maintenance, and Legacy Products

SCORE VALVES supplies original equipment replacement parts and replacement legacy valves, at expedited lead times for all TRICENTRIC® valves manufactured since the mid-1970s, along with customer-focused aftermarket maintenance service at our 30,000 sq ft facility or on-site, as required.

Applications

SCORE VALVES’ extensive 35 years of application experience, with over 30,000 valves installed across all industries, has firmly established SCORE VALVES as a leading butterfly valve solution provider.

SCORE VALVES’ standard and custom solutions for oil & gas and refining are found in all industry sectors—upstream, midstream, and downstream. Worldwide installation by all major end-users is supported by our comprehensive butterfly valve product line from the rugged, non-rubbing TRICENTRIC® triple offset design, to the economical HIGHSEAL® designs.

The versatile TRICENTRIC® triple offset and HIGHSEAL® valves are supplied in multiple material configurations, styles, and options for reliability and optimization of chemical and petrochemical process applications.

SCORE VALVES’ has 35 plus years of experience with power applications including conventional, renewables, and nuclear with major end-users including GE, Mitsubishi, Ameren, EXEL, Duke, Exelon, Florida Light & Power, and Nine Mile among many others. The knowledge gained from installed experience enables SCORE VALVES to meet strict end-user specifications, regulatory compliance, and operating efficiency requirements through the understanding of exacting design and material selection details for ever-increasing temperature and high cycle applications.

SCORE VALVES has been a leader in the cryogenic industry since 1988 with thousands of valves installed worldwide. Our FDA-audited cleaning facility and third-party closure performance testing to NASA and Air Liquide specifications, among others, allow SCORE VALVES to outperform competitors in a wide range of cryogenic applications including air separation units, petrochemical, aerospace, and LNG facilities.

SCORE VALVES’ breadth of experience covers all industries and applications. Our industry reputation of being the go-to specialty valve supplier was accrued through decades of firsthand experience with some of the most stringent and complex applications and specification requirements.